Héméra ArEx is a project that concentrates everything we love: a project that might have a positive environmental impact combined with high technical challenge and cutting edge and innovative technologies.

It was born as a PhD project that aimed to reduce the power consumption and complexity of moving sunshades through the use of Shape Memory Alloys (SMA). The project grew until the company decided to develop a full-scale technology demonstrator in the form of a shipping container.

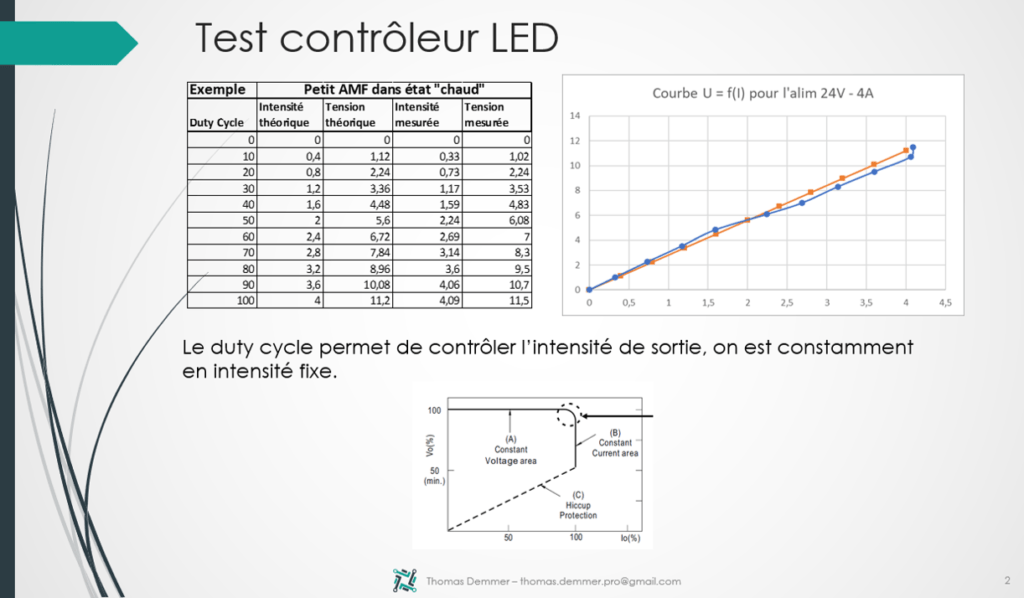

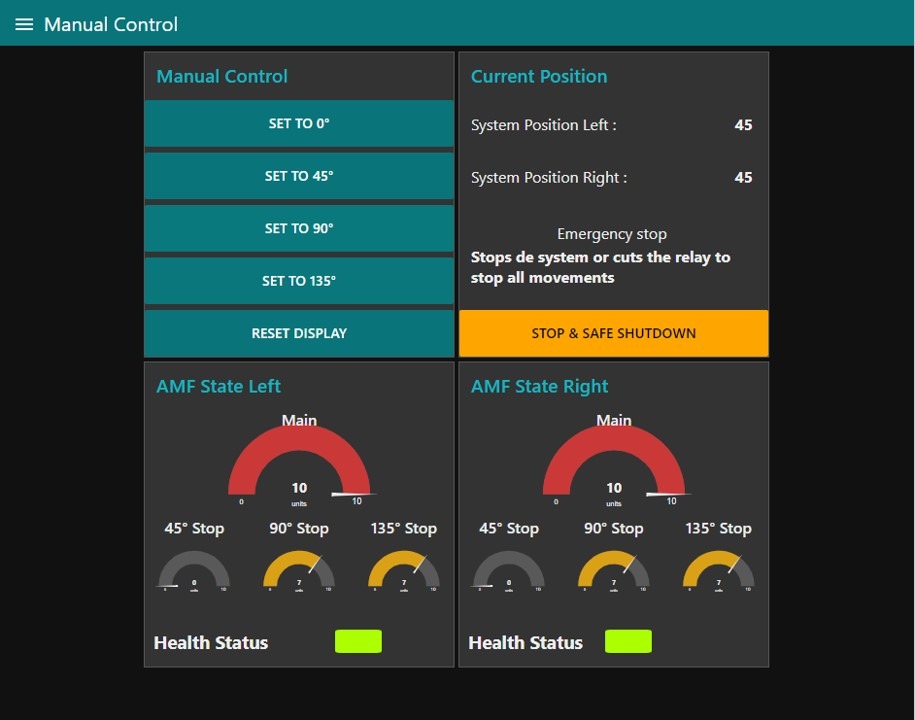

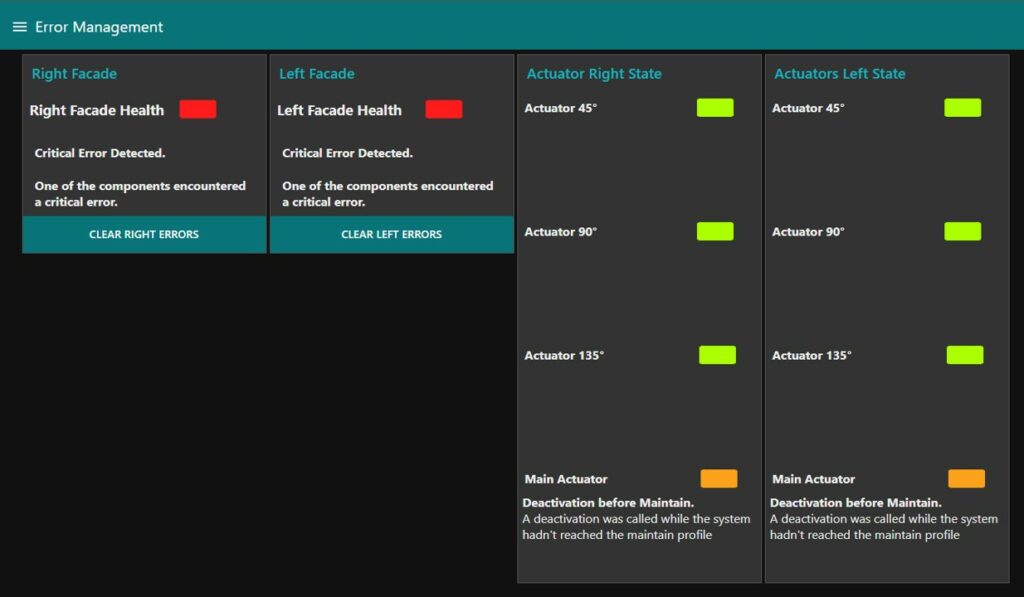

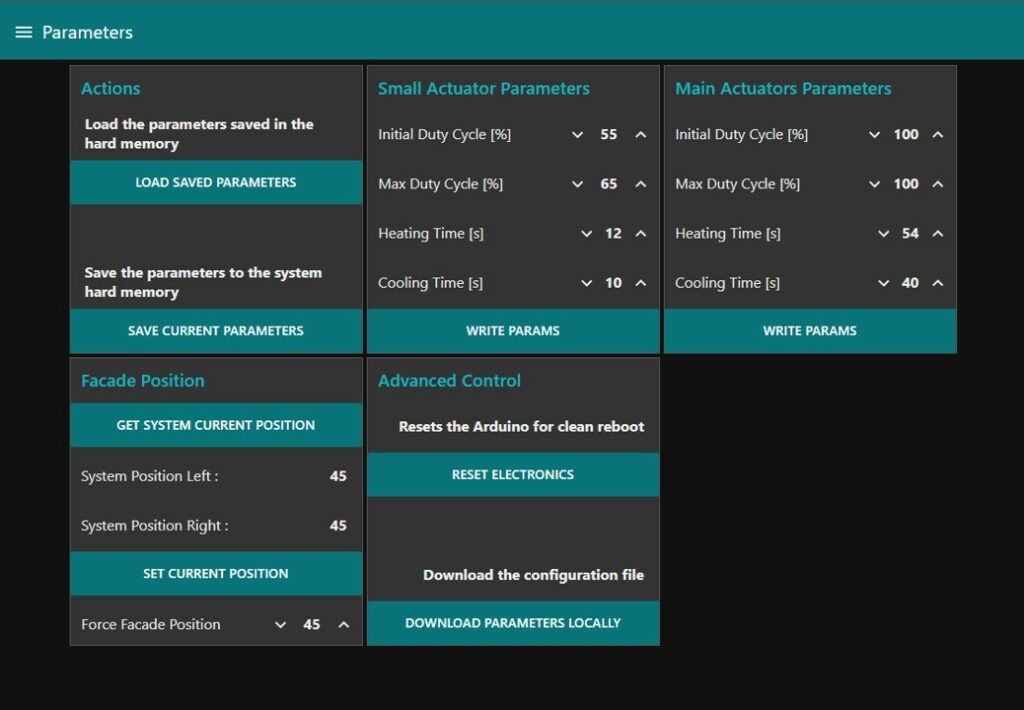

And that is where we stepped-in! The demonstrator required several SMA actuators to work autonomously in a predefined choreography and thus, the development of the hardware and embedded software to have a smooth and reliable movement.

We also contributed to the electrical installation – made even more challenging by the use of innovative solar panels that are embedded in the sunshades – and the development of a simple user interface to operate the shades.

Hemera ArEx is developped by Arcora