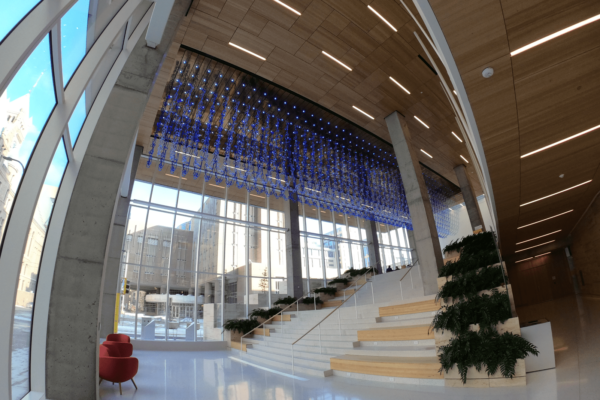

Current Conditions in an elaborate ever-changing piece whose shape and color reflects the changing climate of the City of Minneapolis and the planet. The shape evolves daily and over time.

Each of the 98 chains represent the City’s weather conditions: temperature (light blue) or humidity (dark blue). The light and shape also change at every at sunrise and sunset. The intention of this work is to draw the awareness of the building’s visitors and workers to the environment of which we, as a collective local and global society, are stewards.

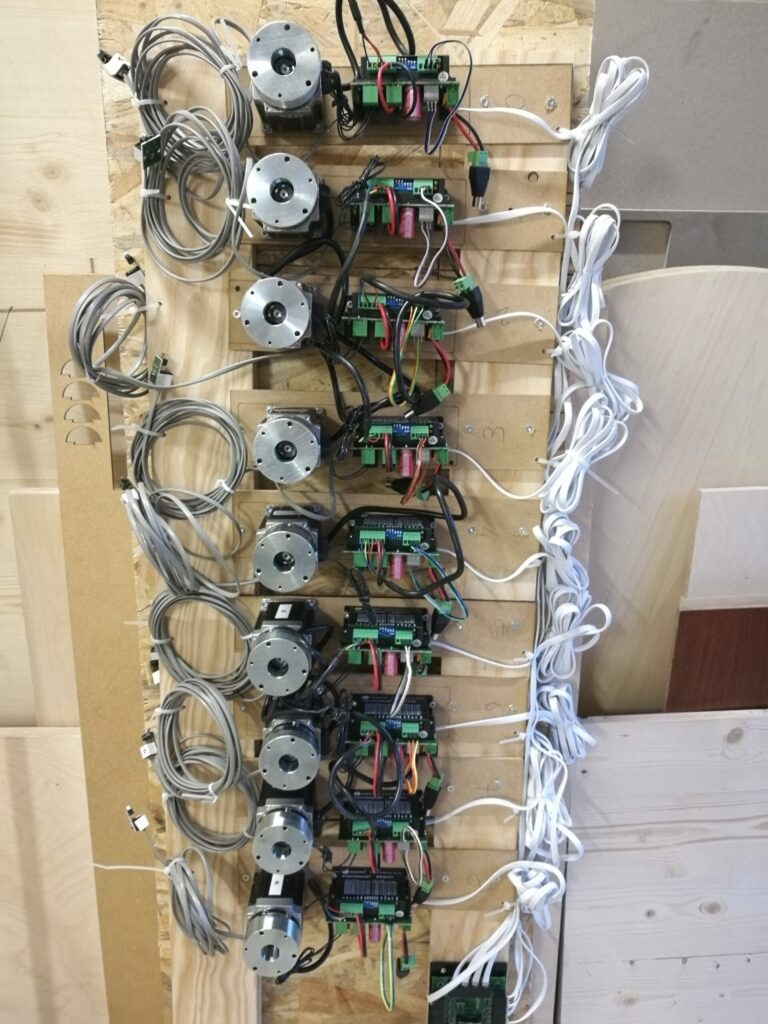

We are immensely proud to have been in charge of all the technical aspects of this project which required many different technical and organizational skills.

Current Conditions is a piece by Tristan Al Haddad, it is permanently installed in the Public Service Building of Minneapolis